Demulsifier Selection Guideline for Destabilizing Water-in-Oil Emulsion for both non-EOR and EOR Application

Published 2023-06-19

Keywords

- Demulsifier selection guideline,

- Relative Solubility Number (RSN),

- Emulsion

How to Cite

Copyright (c) 2023 Nor Hadhirah Halim, Ismail M. Saaid, Sai Ravindra Panuganti

This work is licensed under a Creative Commons Attribution 4.0 International License.

Abstract

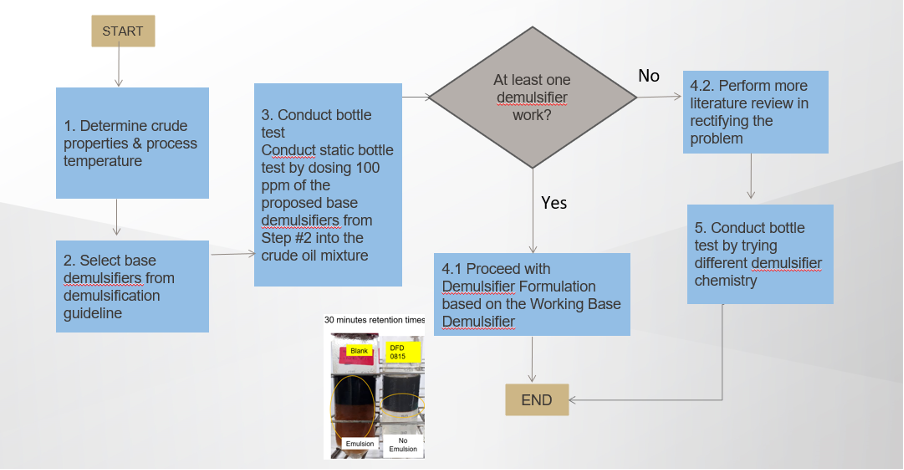

The most common method for resolving water-in-oil (W/O) emulsion is chemical demulsification. Bottle test is a recommended procedure to analyze a combination of essential parameters such as the demulsifier dosage, residence time, heat, degree of agitation to generate the emulsion and agitation effects after demulsifier injection. It is an extensive and time-consuming selection procedure. Furthermore, the previous demulsifier selection guideline reported in the literature had limitations and was not suitable for the Southeast Asia region. This study describes the development of a new demulsifier selection guideline that relates the demulsifier properties to the crude oil characteristics and is more representative for resolving emulsions in Southeast Asia environment. In developing the selection guideline, four types of synthetic crude were used, with the crude API ranging from 27° to 40°. Sixteen demulsifiers with a relative solubility number (RSN) ranging from 11 to 21 were evaluated comprising resin alkoxylate and modified polyol base demulsifiers. An emulsion test matrix was developed by creating emulsions with different wax contents, asphaltene content and solid contents in the crude oil; then, the demulsifier was screened for all the matrices. Based on the demulsification bottle test completion for all the test matrices, the demulsifier selection guideline was developed and then validated with the blind test in resolving emulsions from the actual crude. The validation results achieved an 86.7% match rate between the guideline output and the lab experimental result. This proved that good agreement had been established between the demulsifier properties and the crude characteristics.

References

- B.P. Binks, A. Rocher. (2009) Effects of temperature on water-in-oil emulsions stabilized solely by wax microparticles, J. Colloid Interface Sci. 335 (1), pp 94-104.

- Zaki, N.; Schorling, P. – C.; Rahemian, I. (2000) Effect of asphaltene and resins on the stability of water-in-waxy-oil emulsions, Petrol. Sci. Technol.,18, pp 945-963.

- Angle, C.W. (2001) Chemical demulsification of stable crude oil and bitumen emulsions in petroleum recovery – a review. In Encyclopedic handbook of emulsion technology; Sjoblom, J., Ed.; Marcel Dekker: New York.

- R.L. Marques-Silva, S. Key, J. Marino, C. Guzman and S. Buitriago. (1997) Chemical Dehydration: Correlations between Crude Oil, Associated Water and Demulsifier Characteristics, in Real Systems. SPE 37271-MS, 601-607.

- Cooper, D. G.; Zajig, J. E.; Cannel, E. J.; Wood, J. W. (1980) The relevance of ‘‘HLB’’ to demulsification of a mixture of heavy oil, water, and clay. Can. J. Chem. Eng.,58, p. 576.

- Gent, X., Li, C., Zhang, L., Guo, H., Shan, C., Jia, X., Wei, L., Cai, Y. and Han, L. (2022) Screening and Demulsification Mechanism of Fluorinated Demulsifier Based on Molecular Dynamics Simulation. Molecules MDPI, 27, p. 1799.

- Grenoble, Z., Trabelsi, S. (2018) Mechanisms, performance optimization and new developments in demulsification processes for oil and gas applications, Advances in Colloid and Interface Science, 260, pp 32-45.

- J. Wu, Y. Xu, T. Dabros, and H. Hamza. (2004) “Development of a method for measurement of relative solubility of nonionic surfactants,” Colloids Surfaces A Physicochem. Eng. Asp., 2004, doi: 10.1016/j.colsurfa.2003.10.028.

- Temple-Heald, C.; Davies, C.; Wilson, N.; Readman, N. (2014) Developing New Surfactant Chemistry for Breaking Emulsions in Heavy Oil. SPE-0114-0030, JPT.

- A.M. Al-Sabagh and M.R. Noor El-Din. (2014) Some Factors Affecting the Demulsification Efficiency of Modified Alkyl Benzene Sulfonic Acid in Petroleum Industry. Indian Chemical Engineer, pp. 1-18.

- A.A. Pena, G.J. Hirasaki and C.A. Miller. (2005) Chemically Induced destabilization of Water-in-Crude Oil Emulsions. Ind. Eng. Chem. Res., 44, pp. 1139-1149.

- F. Zhang, G. Liu, J. Ma, J. Ouyang, X. Yi and H. Su. (2017) Main Challenges in Demulsifier Research and Application. IOP Conference Series: Materials Science and Engineering, 167.

- J.J. Scheibel and J.A. Menkhaus. (2005) Modified Alkoxylated Polyol Compounds. WO 2005/063848 A1.

- R.A. Mohammed, A.I. Bailey, P.F. Luckham and S.E. Taylor. (1994) Dewatering of crude oil emulsions 3. Emulsion resolution by chemical means. Colloids and Surface A: Physicochemical and Engineering Aspects. 83, pp 261-271.

- Auflem, I. H. (2002) Influence of asphaltene aggregation and pressure on crude oil emulsion stability. PhD thesis, Trondheim, Norway: Department of Chemical Engineering, Norwegian University of Science and Technology.

- Atta, A.M., Abdel Rahman, A.A.H., Elsaeed, S.M. AbouElfotouh, S. and Hamad, N.A. (2009) Demulsification of Crude Oil Emulsions Using Some New Water-Soluble Schiff Based Surfactant Blends, Journal of Dispersion Science and Technology. 30:5, pp. 725-736.

- Freitas, G. B., Duncke, A.C., Barbato, C.N., de Oliveira, M.C.K, Pinto, J.C., Nele, M. (2018) Influence of wax chemical structure on W/O emulsion rheology and stability. Colloids and Surface A. 558, pp 45-56.

- Ghosh, S., Rousseau, D. (2011) Fat crystals and water-in-oil emulsion stability. Current Opinion in Colloid & Interface Science, 16 (5), pp 421-431.

- R.F.G. Visintin, T.P. Lockhart, R. Lapasin, P. D’antona. (2008) Structure of waxy crude oil emulsion gels. Journal Non-Newtonian Fluid Mechanics. 149, pp 34-39.

- Salager J.L, Forgiarini A.M. (2012) Emulsion stabilization, breaking, and inversion depends upon formulation: advantage or inconvenience in flow assurance. Energy Fuels, 26 (7), pp 4027-4033.

- Perino, A. Noik, C. and Dalmazzone, C. (2013) Effect of Fumed Silica Particles on Water-in-Crude Oil

- Emulsion: Emulsion Stability, Interfacial Properties, and Contribution of Crude Oil Fractions, Energy &

- Fuels, 27, pp. 2399-2412.

- F. Wu et al. (2020) “Investigation of the stability in Pickering emulsions preparation with commercial cosmetic ingredients,” Colloids Surfaces a Physicochem. Eng. Asp., vol. 602, no. May, p. 125082, doi: 10.1016/j.colsurfa.2020.125082.

- Sullivan, A. P.; Kilpatrick, P. K. (2002) The effects of inorganic solid particles on water and crude oil emulsion stability. Ind. Eng. Chem. Res. 41, pp 3389−3404.

- Colin L. LaBerge and David R. McCoy (1982) “Demulsification of Bitumen Emulsions with a High Molecular Weight Polyol

- Containing Discrete Blocks of Ethylene and Propylene Oxide,” 4,321,147.

- D. Chen, H. Zhao, K. Liu, Y. Huang, and B. Li (2021) “The effect of emulsion and foam on anti-water coning during nitrogen foam injection in bottom-water reservoirs,” J. Pet. Sci. Eng., vol. 196, p. 107766, doi: 10.1016/j.petrol.2020.107766.

- N. Borhan, N. H. Halim, and J. M. B. M. Ibrahim (2014) “An investigation of micro-emulsion and fine foams induced by EOR application in Malaysian fields,” Soc. Pet. Eng. - Int. Pet. Technol. Conf. 2014, IPTC 2014 - Innov. Collab. Keys to Afford. Energy, vol. 1, pp. 548–562, 2014, doi: 10.2523/iptc-17762-ms.

- D. Nguyen, N. Sadeghi, C. Houston. Chemical Interactions and Demulsifier Characteristics for Enhanced Oil Recovery Applications. Energy & Fuels, 12th International Conference on Petroleum Phase Behaviour and Fouling, 2012.

- M. Yimei (2014) “Research on Demulsification Mechanism of Polymer Surfactant Flooding Produced Fluid,” vol. 6, no. 1, pp. 15–21.

- R. Zhang, C. Liang, D. Wu, and S. Deng. (2006) “Characterization and demulsification of produced liquid from weak base ASP flooding,” Colloids Surfaces a Physicochem. Eng. Asp., doi: 10.1016/j.colsurfa.2006.05.023.