Published 2021-03-22

Keywords

- Slime and sludge de-watering,

- bubble column evaporator,

- silica spheres,

- helium gas

How to Cite

Copyright (c) 2020 Mohammad Ziaee, Mojtaba Taseidifar, Richard M. Pashley, Barry W. Ninham

This work is licensed under a Creative Commons Attribution 4.0 International License.

Abstract

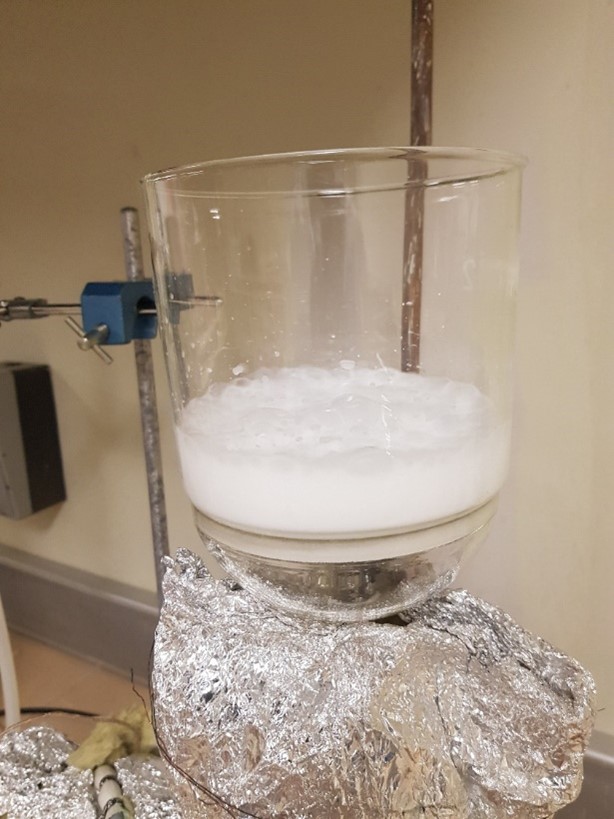

The recalcitrant nightmare of de-watering slime/sludge is a major issue, for both industry and the environment. A simple process is developed that solves the problem. It uses a bubble column evaporator (BCE) with heated dry air. The model slime to illustrate the de-watering process was a concentrated dispersion of spherical 5 micron silica particles in pure water. Typical slime samples were de-watered in the range 20-35% colloid/water (w/w) using dry inlet gases pre-heated to temperatures of 150°C and 250°C. The BCE process was run at sub-boiling temperatures, with the column solution in the range, 43°C and 74°C, with those two inlet temperatures operating for de-watering the slime. A significant bonus is that the pure water vapour produced can be condensed and used as a source of high-quality water for reuse. The BCE process offers simplicity, resilience to slime feed quality, and a pure water biproduct. It also offers a continuous and controlled low-maintenance process. These are clear advantages in de-watering a wide variety of industrial slimes and sludges. In addition, the process involves the passage of a continuous flow of hot dry gases. This causes the dispersion to remain sufficiently fluid to allow easy transportation. However, once the hot gas flow ceased, the dispersion immediately solidified. The success of the bubble column process for dewatering and validation of the mechanism is even more enhanced if helium is used instead of air. It appears that hot helium atoms can disrupt water hydrogen-bonding in the liquid surrounding the hot bubbles and this enhances water vapour collection efficiency. The bubble method appears to offer more than significant advantages over other methods, such as hydrocyclone methods, which are often used to de-water mining wastes.

References

- N.C. Lockhart, Electro-osmotic dewatering of fine tailings from mineral processing, Int. J. Miner. Process., 1983, 10(2), 131-140.

- T.J. Laros, Flocculating agent combinations for mineral slime filtration systems, 1990, Envirotech Corp, United States Patent, Patent No: 4,931,190.

- P. Pirkonen, B. Ekberg, Chapter Nine – Ultrasonic, Prog. Filtr. Sep., 2015, 399-421.

- S. Pasquier, J.J. Cilliers, Sub-micron particle dewatering using hydrocyclones, Chem. Eng. J., 2000, 80(1), 283-288.

- J.J. Cilliers, L. Diaz-Anadon, F.S. Wee, Temperature, classification and dewatering in 10 mm hydrocyclones, Miner. Eng., 2004, 17(5), 591-597.

- D. Vega-Garcia, P.R. Brito-Parada, J.J. Cilliers, Optimising small hydrocyclone design using 3D printing and CFD simulations, Chem. Eng. J., 2018, 350, 653-659.

- G. Chen, P. Lock Yue, A.S. Mujumdar, sludge dewatering and drying, Drying Technol., 2002, 20(4-5), 883-916.

- C. Fan, R.M. Pashley, Precise Method for Determining the Enthalpy of Vaporisation of Concentrated Salt Solutions Using a Bubble Column Evaporator. J. Sol. Chem., 2015. 44(1), 131-145.

- C. Fan, M. Shahid, R.M. Pashley, Studies on bubble column evaporation in various salt solutions, J. Sol. Chem., 2014, 43(8), 1297-1312.

- M. Francis, R.M. Pashley, Application of a Bubble Column for Evaporative Cooling and a Simple Procedure for Determining the Latent Heat of Vaporization of Aqueous Salt Solutions, J. Phys. Chem. B, 2009, 113(27), 9311-9315.

- M.J. Francis, R.M. Pashley, Thermal desalination using a non-boiling bubble column. Desalination and Water Treat., 2009, 12(1-3), 155-161.

- M. Shahid, R.M. Pashley, A study of the bubble column evaporator method for thermal desalination, Desalination, 2014, 351, 236-242.

- M. Taseidifar, M. Shahid, R.M. Pashley, A study of the bubble column evaporator method for improved thermal desalination, Desalination, 2018, 432, 97-103.

- X. Xue, R.M. Pashley, A study of low temperature inactivation of fecal coliforms in electrolyte solutions using hot air bubbles, Desalination and Water Treat., 2016, 57, 9444-9454.

- M. Shahid, A study of the bubble column evaporator method for improved sterilization, J. Water Process. Eng., 2015, 8, 1–6.

- A.G. Sanchis, M. Shahid, R.M. Pashley, Improved virus inactivation using a hot bubble column evaporator (HBCE), Colloids Surf. B: Biointerfaces, 2018, 165, 293-302.

- A.G. Sanchis, R.M. Pashley, B. Ninham, Virus and bacteria inactivation by CO2 bubbles in solution, NPJ Clean Water, 2019, 2, 5.

- M. Shahid, R.M. Pashley, M. Rahman, Use of a high density, low temperature, bubble column for thermally efficient water sterilisation, Desalination and Water Treat., 2014, 52, 4444–4452.

- M. Shahid, X. Xue, C. Fan, B.W. Ninham, R.M. Pashley, Study of a novel method for the thermolysis of solutes in aqueous solution using a low temperature bubble column evaporator, J. Phys. Chem. B, 2015, 119 (25), 8072–8079.

- C. Fan, R.M. Pashley, The controlled growth of calcium sulfate dihydrate (gypsum) in aqueous solution using the inhibition effect of a bubble column evaporator, Chem. Eng. Sci., 2016, 142, 23-31.

- P.N. Govindan, G.P. Thiel, R.K. McGovern, J.H. Lienhard, M.H. Elsharqawy, Bubble-Column Vapor Mixture Condenser, 2013, United States Patents, Patent No: US 8.523,985 B2.

- G.P. Narayan, J.H. Lienhard, Thermal Design of Humidification– Dehumidification Systems for Affordable Small-Scale Desalination, IDA J. Desalination Water Reuse, 2012. 4(3), 24-34.

- M. Schmack, H. Goen, A. Martin, A Bubble Column Evaporator with Basic Flat-plate Condenser for Brackish and Seawater Desalination, Environ. Technol., 2015, 37(1), 74–85.

- M. Shahid, C. Fan, R.M. Pashley, Insight into the bubble column evaporator and its applications, Int. Rev. Phys. Chem., 2016, 35(1), 143- 185.

- A. Stocco, E. Rio, B. P. Binks, D. Langevin, Aqueous foams stabilized solely by particles, Soft Matter, 2011, 7(4), 1260-1267.